Differentiating Value-Added Services & Solutions

Custom solutions in engineering and sourcing, logistics, product enhancement, inventory management and more. Our value-added services help make your job easier by making cables easier to identify, faster to install, and tailored to your specific needs. You’ll save time and money while avoiding the headaches that come with using stock cables.

Engineering and Sourcing

Engineering design for automation systems and custom cabling and supply chain support services for inventory management and shipping optimization.

- Engineering and custom cabling design solutions for unique applications

- Just-in-time delivery to reduce stock-outs

- Provide access to cost-effective supplier options

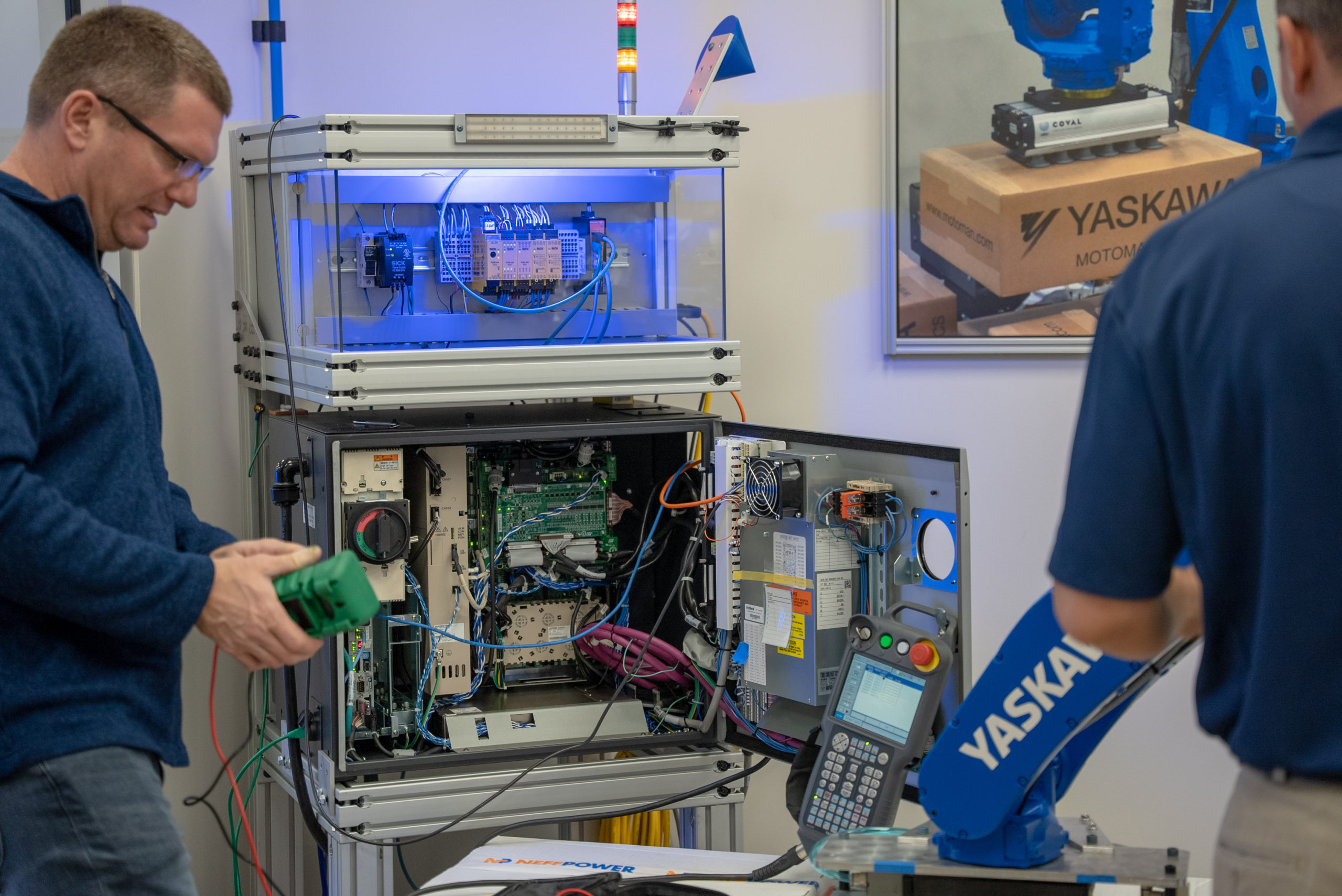

Custom Assembly Experts

Superior manufacturer of standard and custom cable assemblies, wire harnesses, box-builds and other electromechanical builds including molded and multi-conductor assemblies. We utilize automation and lean manufacturing for efficiency and speed of production.

- Requires specific product expertise

- Reduces customer assembly time / errors

- Reduces inventory and increases efficiency

Product Enhancement

Cut & Strip

Instead of manually cutting each piece of wire from the reel, then removing the insulation from the ends, save time and money by letting us take care of it for you.

Ink Jet Printing

Ink Jet Printing marks the cable using dots of ink. This makes identification and custom branding easy. Save time in the installation process with proper labeling.

Dyeing

A variety of wire can be dyed to help facilitate proper identification for existing or custom installation. We can color match and dye to meet individual specifications.

braiding

Braiding helps add protection to avoid abrasion in harsh environments. Save time by having us braid your wire, cable, or twisted wire.

twisting

Twisting wires cuts installation time dramatically by allowing wires to lay together well and making them easier to work with. Letting us handle it saves even more time.

drum Packing

Make your wire easy to store and unroll when needed by having us drum package it. Thousands of feet of wire (depending on gauge) can be stored on a single drum.

extruding

Help protect and insulate wire with extruding. Your wire will last longer, and you’ll save time and money on future replacements.

Taping

We can add a tape jacket to your cable in order to group individual wires together creating a multi-conductor cable, as well as adding a little extra protection from wear.

Striping

Wire striping makes cable identification simple. Your application will stay organized, saving you time locating wires during installation and maintenance.

Material Management

Kitting and Staging

Just in Time Delivery

Job-site services

Shipping optimization